The popularity and concerns of LNG-powered vessels

Checking and controlling carbon emissions is vital for the growth and sustenance of the maritime industry. LNG-powered vessels are anticipated to witness significant growth in the market share, as environmental regulations become more rigid. LNG Ships produce 25% fewer carbon and nitrogen emissions.

Moreover, LNG is more affordable compared to the costly low-sulfur heavy oil, which is now being popularly used by most ocean-going vessels.

There has been a tremendous increase in the transportation of LNG, as the value and scope of the LNG trade have risen. Larger ships are now the norm, short-term contracts are becoming more common, and the spot market is becoming more active.

There are, however, some safety drawbacks that must be taken into consideration. Many serious tanker fires have occurred in recent years. In March 2017, a Chinese tanker exploded, causing extensive damage to the vessel and the disappearance of three crew members. In another incident, an explosion claimed the lives of five crew members during a mission in central China in 2012.

The LNG tanker Fuwairit, owned by the Japanese shipping company Mitsui OSK lines, leaked vapour into the port of Barcelona in 2015. In Navantia-Ferrol, they had to fix four cracks in the ship’s deck after a valve and a high-level alarm failed simultaneously. At tank No. 1’s top, a “pool” of floating LNG had developed, and when it came into contact with salt water, it vaporized, creating a gas cloud that can be seen by the condensation of seawater vapour.

A record number of LNG tankers leave Canada’s west coastlines every year, en route to destinations as far afield as Europe and Asia. As a result, the vast majority of tankers now traverse narrow waterways and densely populated areas. As a result, the potential dangers of LNG ships in these waters should never be underestimated.

Advantages of LNG as a marine fuel

LNG can be defined as a gas that has been cooled to a liquid state for the purpose of storage and transportation. Natural gas in a gaseous state occupies approximately 1/1600th of the volume of LNG in a liquid condition. It’s the cleanest fossil fuel and a green energy source that has attracted many industrial sectors including the maritime.

Liquefied natural gas is made up of a variety of hydrocarbons such as methane, butane, propane, and propylene, as well as a trace amount of nitrogen. The exact composition of LNG varies, depending on the source and liquefaction procedure used.

LNG typically contains 85- 95% methane by weight. Liquid nitrogen, sometimes known as “liquid helium,” has a density of 426kg/m3. When it comes to transporting and storing LNG, double-walled containers are used to keep it cool and decrease the chance of leaking.

Because of its ability to satisfy regulatory standards, improve air quality, and reduce greenhouse gas emissions while also lowering costs, switching to LNG can have considerable benefits.

The EEDI rating of LNG-fueled ships can be reduced by 20%, and the Carbon Intensity Indicator can be reduced by around the same percentage. Compared to conventional designs, competitive vessel design provides compliance for an additional ten years after construction is complete.

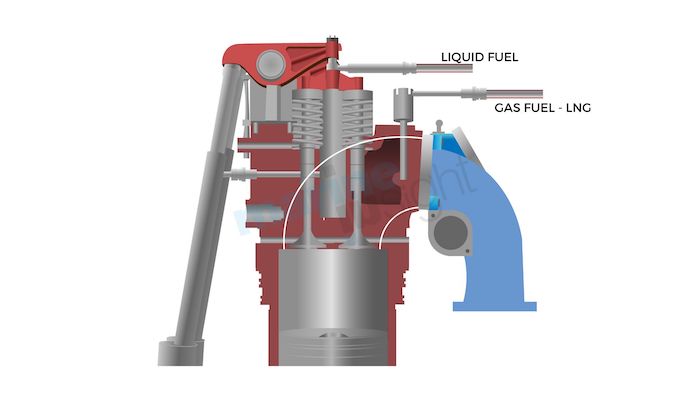

Modern engine technology can cut particulate matter (PM) GHG emissions by up to 23% while reducing NOx emissions by up to 80% and nearly eliminating sulphur oxide emissions. Drop-in fuels and biogas are other options for decreasing the carbon intensity of vessels.

When consumed, LNG releases fewer nitrogen oxides and carbon dioxide than other fossil fuels because it removes sulfur during the pre-liquefaction process. As a result, LNG is believed to have a minimal environmental impact.

When it comes to LNG-powered ships, the number has grown from a total of 18 operational ships in 2010 to 175 already in operation and more than 200 on order in 2020.

Ensuring safety on LNG vessels

There are a lot of steps that need to be taken before a ship can transport LNG. The following are some examples of LNG operations:

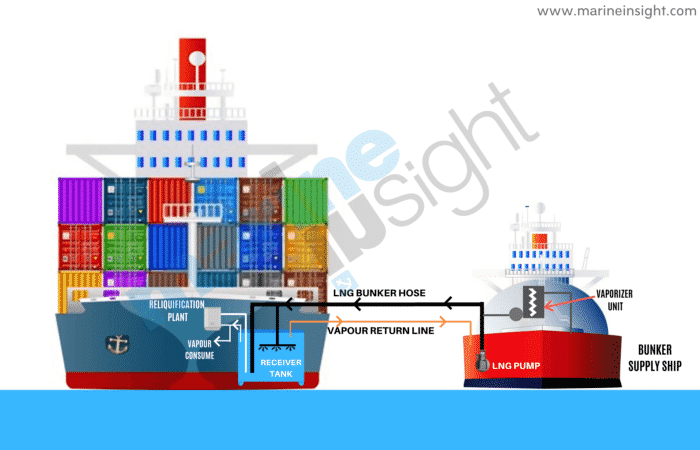

Transfer Procedure: In order to provide safe and efficient loading of LNG, the loading procedure should be carried out in a timely manner after getting the authorisation from the Coast Guard. When loading LNG, the compatibility of the ship and the transfer space are two critical considerations. Weather conditions, appropriate lighting and warning indications are also crucial.

Pre-loading operations: Checking tanks and other equipment, inspecting bunker Hoses and connecting hoses are some of the pre-loading procedures.

Bunkering operations: Transfer lines and the liquid filling line are both sanitized during bunkering operations. In addition, it involves the return of Documents and the ready signal.

After the bunkering procedure is complete, there are still a few things that need to be done. Disconnecting the communication linkages and stripping the transfer lines and hoses are all part of the process.

To ensure the safety of the liquefied natural gas onboard, it must be stored in specially engineered shore tanks. Single containment tanks, double containment tanks, and full containment tanks are the most common types of tanks used to store LNG. A backup tank is always maintained, in case there is a leakage.

LNG is transported through specialised ships that are specifically designed for this task. Membrane tanks and Moss Rosenberg tanks are generally in use today. The International Gas Carrier (IGC) 1986 code and SOLAS 74 chapter VII part C compliance check is required for LNG vessels operating on international seas, according to the International Maritime Organization.

When LNG is exposed to air, it burns in an instant, since it is inflammable.

Ships transporting LNG face significant dangers, including Vapour Cloud Explosions, Fumigation, Spills or leakages, Freezing liquids, LNG rollover, Rapid state transition of LNG, and Sloshing. The first four on the list pose a serious threat to marine life and the environment.

In the event of an explosion on an LNG ship, the flames produced by LNG have a longer lateral reach and higher elevation, putting the lives of the crew in danger. A gas leak in an LNG ship is the most hazardous, especially in the engine room, motor rooms, and cargo compressor. To ensure crew safety, the ship must have CO2 fire suppression systems in these high-risk zones.

Safety measures such as installing fire suppression systems on all machinery and using smart ultrasonic technology can increase safety levels for both the ship and its crew.

A vapour cloud explosion may occur if LNG leaks from ships, leading to a rapid spread of flames and potential re-explosion. Excessive thermal strains from the cooling process in the LNG storage tank can damage the ship’s hull.

Leaks and spills involving LNG can result in cryogenic burns, asphyxiation, flames, explosions, and dispersion, posing a serious threat to public health and safety. Modern strategies, including the use of high-quality safety equipment and regular inspections, can help reduce LNG spills.

Fumigation, caused when LNG reacts with air, can lead to suffocation and environmental hazards. Proper maintenance of equipment like filters, valves, and regulators, along with efficient ventilation and exhaust systems, can help mitigate the effects of fumigation.

In conclusion, as LNG shipping grows and becomes a popular alternative to oil, implementing necessary safety measures is crucial. The transportation and freight industries are embracing eco-friendly fuels, emphasizing the importance of safety in transporting LNG worldwide. different words while keeping the same meaning.