Revolutionizing Port Operations: DynaMoor Mooring System Trial Begins in Japan

NYK, JERA, and Trelleborg Marine & Infrastructure (TMI) have joined forces to introduce a cutting-edge DynaMoor mooring system at the coal unloading berth of JERA’s Hitachinaka Thermal Power Station in Ibaraki Prefecture, Japan.

DynaMoor, a state-of-the-art mooring system, is designed to minimize ship sway and surge while vessels are docked at the berth. This innovative system aims to enhance the safety and efficiency of port operations.

As part of the trial, two DynaMoor units have been installed at the designated berth and will undergo rigorous testing for a duration of one year. Motion sensors will be attached to berthed vessels to monitor vessel-hull sway and surge while utilizing DynaMoor, allowing for the assessment of its effectiveness in reducing ship motion.

Many ports situated facing the open sea are susceptible to swells and long-period waves, which can disrupt cargo operations. Ship sway often necessitates moving vessels out of port, leading to inefficiencies in cargo handling.

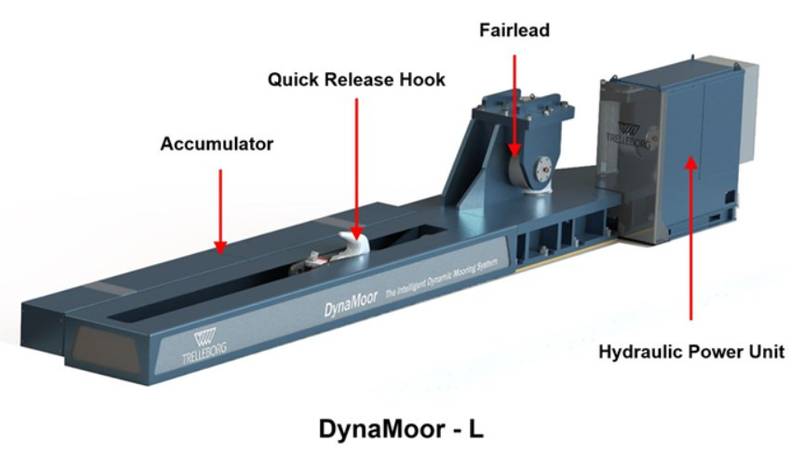

Traditionally, controlling ship sway by adjusting mooring line tension from the vessel has proven challenging. DynaMoor, developed by TMI, offers a solution by automatically adjusting mooring line tension to stabilize a ship’s hull movement.

The system utilizes an electronically controlled hydraulic damper to move the quick-release hook connected to the mooring line along a rail, responding to the ship’s hull movement and effectively reducing sway and surge.

This trial signifies a significant step towards transforming port operations and addressing challenges associated with ship motion at berths. The successful implementation of the DynaMoor mooring system could revolutionize the maritime industry’s approach to vessel mooring and enhance operational efficiency across port facilities.