The Evolution of Hull Coating Performance Monitoring in the Maritime Industry

There’s a tendency for owners to stick with the coatings they are familiar with, but environmental concerns, particularly regarding marine biodiversity, are providing fresh opportunities for them to reconsider.

Measuring hull coating performance from noon reports yields around 350 data points over a five-year docking cycle after including full loaded sailing days and excluding adverse weather days etc.

But it’s become a more sophisticated challenge now that owners and operators have to factor in decarbonization regulations, the IMO’s 2023 biofouling guidance for invasive species prevention (MEPC 378.(80)) and the potential for reputational damage if a vessel is denied entry to a destination port.

As a result, technology for coating performance monitoring and prediction is growing in sophistication perhaps faster than coating technology itself.

High frequency monitoring is becoming more popular as it can provide hundreds of readings a day. The systems that coatings suppliers are advancing are typically based on historic AIS data which is to determine voyage route and speed combined with seawater temperature data to estimate fouling challenges.

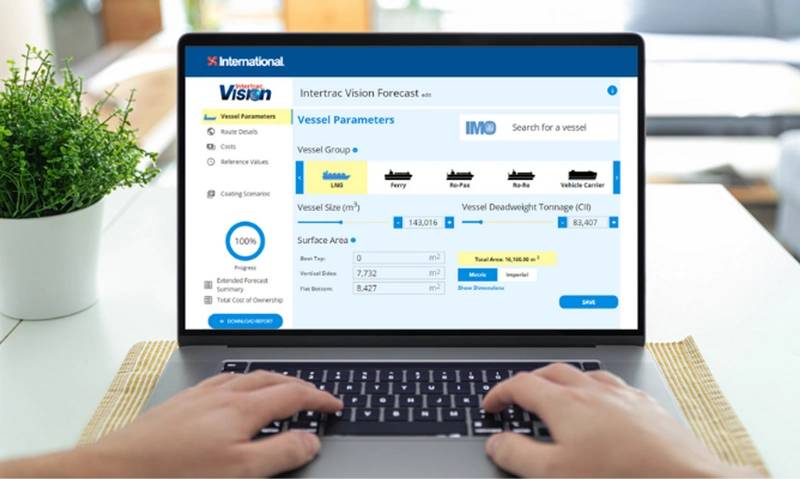

AkzoNobel’s International marine coatings brand has released updates to its digital forecasting tool, Intertrac® Vision which include the ability to predict CII ratings and assess the financial impact of the EU’s Emissions Trading System. Intertrac Vision draws from a database of over 200,000 drydocks and 10,000 vessel operations. It combines this historical data with machine learning to forecast the impact of coatings on a vessel’s performance. A new update now provides a total cost of ownership summary, breaking down the cost contributions of each stage in the drydocking cycle. Additionally, users can now forecast over a 120-month cycle either as two consecutive 60-month dockings or one continuous period.

Jotun’s fouling risk management program HullKeeper uses advanced big data analytics and includes the company’s proprietary algorithm that aims to identify risks and provide recommended actions for maintaining a clean hull. Upcoming developments include integrating performance analytics with the algorithm output and the ability to register events.

“The mission to protect biodiversity has gained more and more focus, as we saw at both COP29 and at the Glofouling R&D Forum, both taking place in November,” says Morten Sten Johansen, Global Category Director Hull Performance, Jotun. “The trend is to have focus on transfer of invasive aquatic species and not only on decarbonization of shipping, although it is linked together through biofouling.”

Kazuaki Masuda, Corporate Officer, Technical Division Director at Nippon Paint Marine, says that as the industry’s regulatory landscape becomes more complex, customers increasingly expect insightful data that demonstrates a coating’s impact on vessel performance, particularly in terms of compliance with the IMO’s GHG strategy to reduce emissions. Nippon Paint Marine offers a proprietary methodology along with CII predictions

Carl Barnes, Head of Marine Consulting at Safinah, says optimal biofouling protection can be achieved through informed product selection and specification, controlled application and installation, monitoring and appropriate maintenance. “For example, based on Safinah’s knowledge of antifouling schemes, a significant difference in scheme thickness (the dry film thickness applied) can be needed for what appears as relatively minor changes to the scheme parameters. A relatively small increase in predominant sea surface temperature of 3oC (moving from 25oC to 28oC) could require a significant increase in the antifouling scheme thickness, typically, up to 30%.

“Furthermore, other factors such as application location, season, product availability, biofouling management options, cleaning equipment availability at typical destinations, and many others also need to be considered.”

Barnes says that the choice of hull coatings can be a minefield with over 150 products for fouling control available on the market from the main coating’s suppliers, all making performance claims.

“However, based on our data from the dry dock returns, there is no real difference between the performance of perceived low and high technology levels. Furthermore, more than half of the ships with >20% macrofouling (animal or weed) on arrival in dry dock opted for the same coating manufacturer and often the same product.”

Coating decisions extend beyond the hull, and Barnes notes a shift away from coating propellers with silicone foul release coatings, as these coatings have poor anti-abrasion properties and are easily damaged, typically suffering from cavitation damage at the propeller blade tips. Epoxy technology is becoming popular instead.

In the last couple of years, Subsea Industries’ sister company Hydrex has noted a substantial increase in the number of enquiries for underwater rudder repairs and offers its Ecoshield coating to protect against cavitation damage. The company has also had success with the coating for preventing corrosion damage in scrubber tanks, pipes and outlets.

Recognizing that coatings themselves are an important asset, Lloyd’s Register (LR) awarded the maritime industry’s first Enhanced Antifouling Type Approval to GIT Coatings last year. The establishment of the advanced approval is a direct response to the IMO’s 2023 biofouling guidance for “The Control and Management of Ships’ Biofouling to Minimize the Transfer of Invasive Aquatic Species.” The idea is to provide owners and operators with validated assurance that a coating maintains its performance before and after grooming, with no roughness increase and no thickness loss, and is compatible with the vessel’s planned grooming frequency.

In developing the new type approval, Heather Hughes, Team Leader for Non-Metallics and Coating Materials at LR, reached out to coatings manufacturers to gather data on the cleanability and performance of their coatings. This data included scientific measurements, although there are no international test standards for proving cleanability at present. LR is therefore collaborating with laboratories, including Plymouth Marine Laboratory, DHI in Scandinavia and Geoffrey Swain at the Florida Institute, to develop standards for verifying the performance of anti-fouling coatings through independent verification.

Next, Hughes expects type approval for cleaning equipment to ensure it does not negatively impact coatings.

She has already seen an exponential shift in the coatings market that is driven by economic and reputational factors, but, hearteningly and surprisingly, more strongly driven by the industry’s environmental concerns.