The Future of Offshore Wind: Baker Hughes Innovates with High Voltage Wet Mate Connectors

Offshore wind energy is a rapidly growing sector, with floating wind turbines emerging as a promising solution for harnessing renewable energy resources. Baker Hughes, a global leader in energy technology, is at the forefront of innovation with their high voltage wet mate connectors designed to revolutionize the industry.

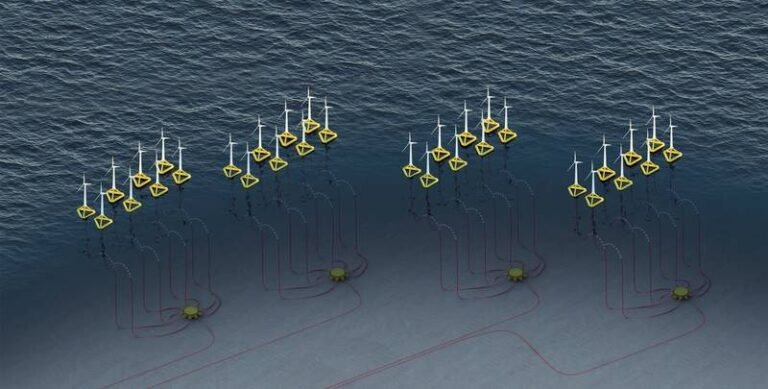

The 66kV high voltage wet mate connector developed by Baker Hughes is a game-changer in offshore wind technology. Weighing over one ton and filled with dielectric oil, this connector can handle copper cables up to 1,200 square millimeters in diameter. Its primary function is to connect dynamic cables from floating wind turbines to a collector hub on the seabed, ensuring efficient power transmission to subsea substations and eventually to shore.

Addressing Cable Failure Challenges

Cable failure is a significant concern in offshore wind operations, especially with dynamic cables used in floating wind applications. Baker Hughes has leveraged its expertise in the oil and gas industry to redesign their Marine Electrical Connectors (MECON) high voltage AC wet mate connector. Unlike traditional single-phase connectors, Baker Hughes’ three-phase connectors offer superior insulation and minimize potential leak paths, enhancing reliability and performance.

Mike Birch, Product Manager for Offshore Power Systems at Baker Hughes, explains, “Our system consolidates three individual phase connections into a single mechanical connector, reducing the risk of leaks and improving overall efficiency.”

ROV Flushable and Simplified Design

The wet mate connectors are ROV flushable, allowing for easy installation and maintenance. By flushing the connector-collector interface with seawater, followed by fresh water and ethanol, before injecting dielectric oil, the connectors ensure a secure electrical connection.

Baker Hughes’ collector hub design aims for simplicity and cost-effectiveness. With no moving parts and a focus on standardization, the collector hub streamlines power collection from multiple turbines to a single output, eliminating the risks associated with daisy-chaining cables.

Driving Industry Standardization and Future Growth

Baker Hughes is working closely with energy majors to qualify their new connectors for the evolving offshore wind market. As the industry moves towards 66kV and beyond for larger turbines, standardization and scalability become crucial for cost-efficiency and sustainability.

With projections estimating significant growth in floating wind capacity, Baker Hughes’ innovative solutions are poised to play a vital role in achieving renewable energy targets. The company’s focus on structured building blocks and efficient power transmission systems sets the stage for a sustainable future in offshore wind energy.

Looking Ahead

As the offshore wind industry continues to evolve, Baker Hughes remains committed to advancing connector technology. With plans to address the growing demand for 132kV systems and larger turbines, the company is poised to lead the way in powering the future of offshore wind energy.